Gas Conditioning

Gas Conditioning Solutions

ARC Energy Gas Conditioning Solutions – ARC’s fuel gas conditioning system is designed to purify fuel gas so that it can be more efficiently utilized. Gas conditioning enhances the quality of the fuel by getting rid of unnecessary particles and condensate while regulating temperature and pressure. ARC Energy applications can meet your needs for key applications such as:

- Dew Point Control

- NGL Recovery

- Drilling Rig Engine Fuel

- Compressor Fuel

- Plant Instrument Gas

- Fired Equipment Burner Fuel

ARC Energy can help determine which products are best-suited for your specific needs by assessing temperature requirements, pressures, timing, recoverability, environment and all conditions to best capture efficiencies and desired outputs.

- Coolers

- Condensate Stabilizers

- Fuel Gas Skid

- Gas Conditioning Skid

- Gas Production Unit (GPU)

- Glycol Dehydrator

- Horizontal Heater Treater

- Indirect Line Heater

- JT Skid

- Vertical Heater Treater

Key Benefits

- Flexible Leasing and Rental Contracts

- Trailer Mounted Units are Available to Provide for More Mobility

- Start-Up Assistance with ARC Service Personnel

- Helps meet Engine Fuel Specifications

- Decreases Wear and Tear on Engines

- Decreases Fuel Gas BTU

- Minimizes Engine Downtime

- Reduces Operational Emissions

- Enhanced safety

- More Cost Effective

- Simple and Safe Maintenance

ARC Services

- Repair of Customers Packages – (Any Brand)

- Rental, Maintenance and Cleaning

- Field Service – Repair and Trouble Shooting

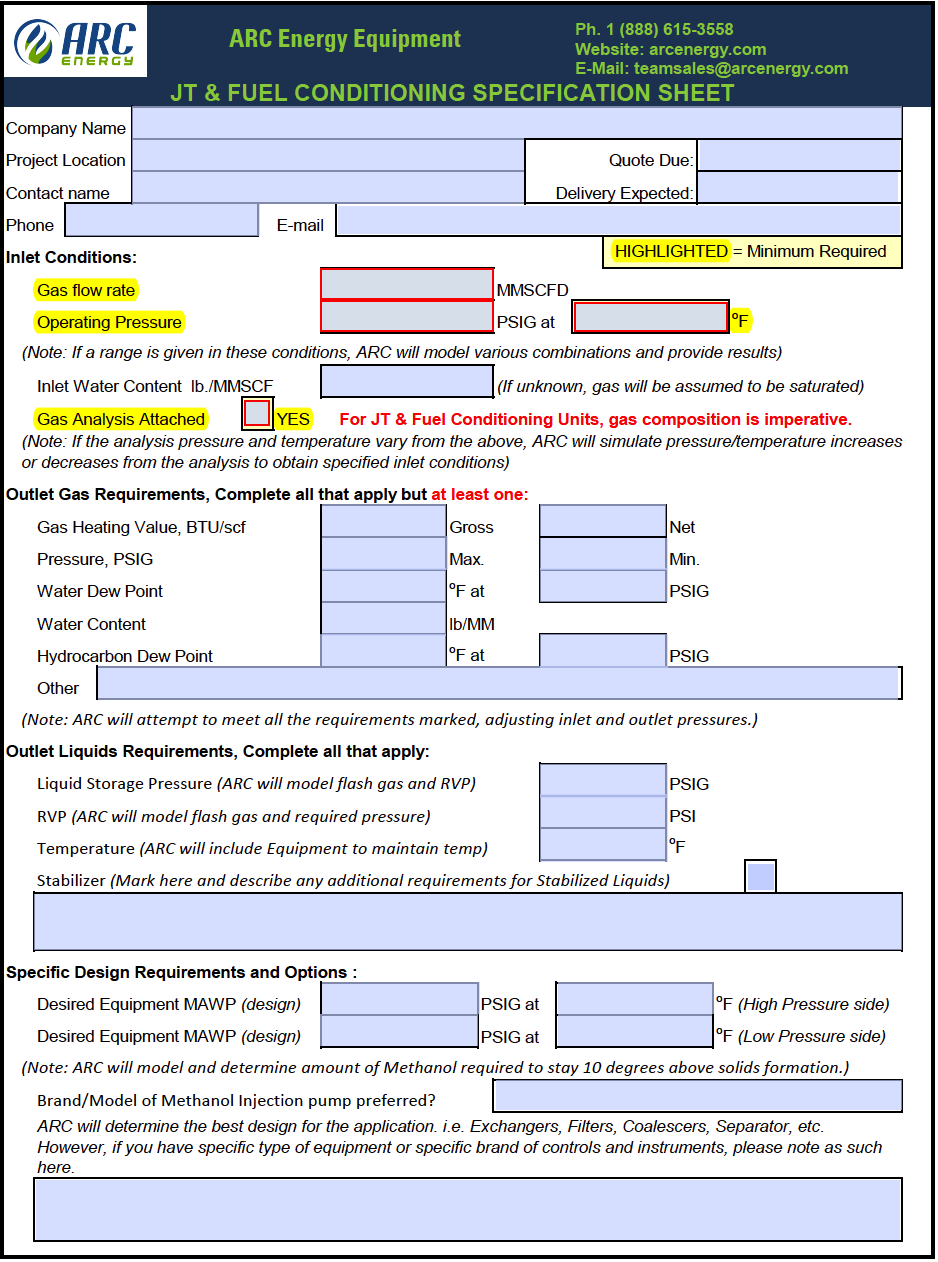

Specification List

Equipment that may be incorporated for Fuel Gas Conditioning Requirements:

Pressure Reduction:

- Regulators or Pressure Control Valves will reduce the inlet pressure to a controlled outlet pressure and will usually require a separator to collect condensed liquids.

BTU, Water Dew Point or Hydrocarbon Dew Point:

- Depending on composition and outlets specs, Coalescing Filters, Desiccant Dryers, JT Units, Dehydrators or combinations will be used.

Impurities/Particles:

- Vessels with Replaceable Filter Elements.

Inert Gas or Sour Gas specifications:

- Specialized Treating equipment may be incorporated to treat H2S or to reduce CO2.

Measurement:

- Many times, gas measurement is incorporated to record fuel usage.

Our dedicated Team of Oil & Gas Specialists work with you from the design phase through start-up and commissioning.

Get Started

Our dedicated Team of Oil & Gas Specialists work with you from the design phase through start-up and commissioning.